Heat is a single common by-product of today‘s manufacturing machines that include the advanced automation technology required for both high speed operation and high precision. Components such as spindle motors, variable frequency drives, laser and x-ray sources all require cooling to operate properly and reliably – most often in the very adverse manufacturing environments.

Marine Vienney

Recent Posts

The 6 Step Guide to Choosing the Best Chiller for your Application

Posted by Marine Vienney on Sep 29, 2016 8:37:21 AM

Topics: Chillers, liquid cooling

Understanding the Different Types of Liquids Used in Chillers for Cooling Processes

Posted by Marine Vienney on Sep 23, 2016 10:51:56 AM

With manufacturing space at minimum, machine packages have become smaller and liquid cooling has emerged as the most efficient and economical means of removing process heat. Chillers often are the only method of providing sustainable efficiency & reliability performances in "hostile" environments.

Topics: Enclosure Cooling, Packaged Chillers, Chillers

Join Pfannenberg at Security Fair in Essen, Germany

Posted by Marine Vienney on Aug 31, 2016 10:47:51 AM

Come join Pfannenberg at "Security 2016" in Essen, Germany from September 27th to 30th - the world leading fair for security and fire prevention - where we will be introducing our latest Industrial Signaling Solutions!

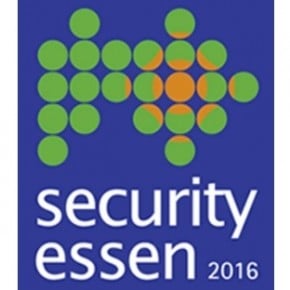

Prevent Summer Overheating with Pfannenberg Enclosure Cooling Solutions

Posted by Marine Vienney on Aug 30, 2016 9:49:16 AM

Preventing enclosure overheating in the summer can be a challenge for many factories, where temperatures can rise fast during hot days!

Topics: Enclosure Cooling, Thermal Management

The Technology of Cooling Part 4: Closed Loop Liquid Cooling Solutions

Posted by Marine Vienney on Jul 29, 2016 9:57:00 AM

Liquid Cooling Solutions like Air to Water Heat Exchangers or Chillers are especially well adapted to hot, dirty environments, where it provides a method of removing the heat from the machine and not contributing additional heat back into the environment.

Topics: Air Water Heat Exchangers, Enclosure Cooling, Water Cooling, Chillers

The Technology of Cooling Part 3: Cooling with Closed Loop Cooling Units

Posted by Marine Vienney on Jul 21, 2016 11:58:32 AM

Pfannenberg cooling units operate on the principle of the Carnot cycle. This means that the cooling units function as a heat pump that “pumps” the thermal energy transferred from the

electronic cabinet (heat dissipated from the components) up to a higher level of temperature (the ambient temperature can reach levels as high as + 55 °C). The air inside the enclosure is cooled down by the evaporator and at the same time dehumidified.

Topics: Enclosure Cooling, Cooling Units, Thermal Management

The Technology of Cooling Part 2: Cooling with Closed Loop Air to Air Heat Exchangers

Posted by Marine Vienney on Jul 15, 2016 2:48:18 PM

Closed Loop Cooling and particularly Air to air heat exchangers are used when the complete separation between the enclosure and the environment is required and the internal enclosure temperature to be cooled can be higher than the ambient.

Topics: Enclosure Cooling, Cooling Units, Thermal Management

Download Pfannenberg's NEW 2016 Thermal Management Catalog!

Posted by Marine Vienney on Jul 8, 2016 9:32:26 AM

We are excited to announce the release of our NEW NORTH AMERICAN CATALOG. In this catalog we take a Solutions First approach to helping you understand how to choose the best Thermal Management products for your applications.

Topics: Enclosure Cooling, Thermal Management, North America

The Technology of Cooling Part 1: Cooling with Filterfans®

Posted by Marine Vienney on Jul 7, 2016 11:56:18 AM

If the installation is in a clean, non-hazardous environment with an acceptable ambient (outside the enclosure) temperature range, a simple forced-air cooling system utilizing outside air is usually adequate. Combined with an air filter, such devices generally meet the heat removal needs of typical electronic equipment and many electrical applications.

Topics: Filterfans, Enclosure Cooling, Thermal Management

Liquid Cooling Solutions, the Best Choice for Complete Plant-wide Machine Cooling

Posted by Marine Vienney on Jun 10, 2016 3:15:06 PM

When it comes to Thermal Management, cooling each machinery or electrical cabinet separately is usually the solution chosen by most of the industries. However, this leave a valuable optimization potential untapped.

Maximum efficiency cooling for a whole system can be achieved with a cooling system solution consisting of air to water heat exchangers and water-based chillers. These 'Liquid Solutions' cool the complete assembly and offer significant benefits compared to traditional approaches such as cooling with ambient air.

Topics: Air Water Heat Exchangers, Enclosure Cooling, Thermal Management, Water Cooling, Packaged Chillers, Chillers