Pfannenberg cooling units operate on the principle of the Carnot cycle. This means that the cooling units function as a heat pump that “pumps” the thermal energy transferred from the

electronic cabinet (heat dissipated from the components) up to a higher level of temperature (the ambient temperature can reach levels as high as + 55 °C). The air inside the enclosure is cooled down by the evaporator and at the same time dehumidified.

How do I know if a cooling unit is the right product for my application?

- If the ambient temperature is greater than the target internal temperature of the enclosure, active cooling is required.

- If indoor NEMA Type 12 applications, NEMA Type 3R/4 outdoor applications and NEMA Type 4/4x stainless steel for washdown applications are required - closed loop cooling can maintain the NEMA Type rating of the cabinet.

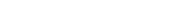

Properly sizing a cooling unit

To properly size your cooling units you must know the required cooling capacity in Watts, mounting requirements (side, integrated or top mount) and the dimensions of the cooling unit and enclosure.

To properly size your cooling units you must know the required cooling capacity in Watts, mounting requirements (side, integrated or top mount) and the dimensions of the cooling unit and enclosure.

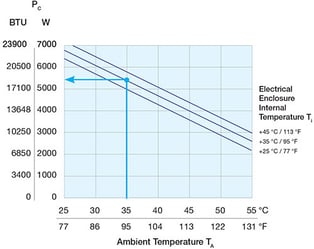

Utilizing performance curves to properly size cooling units:

> Pfannenberg utilizes the DIN standard 35/35 °C when rating our cooling units.

> Many other companies use 50/50 °C, which provides a higher, non-usable value. Customers should use their own application temperatures to determine the proper cooling capacity of the system.

Important information when utilizing cooling units:

Important information when utilizing cooling units: - The refrigeration capacity should exceed the dissipation loss from the installed components by approximately 10%.

- The enclosure should be sealed to prevent the inflow of ambient air.

- Use the door contact switch to impede operation with open doors and consequent excessive accumulation of condensation.

- Use cooling units with maximum clearance between air inflow and air outflow to prevent poor circulation.

- Make sure that the air inflow and air outflow in the external circuit is not hindered, preventing proper heat exchanging at the condenser.

- When using top-mounted cooling units, make sure that components with their own fans do not expel the air directly into the cooling units cool air outflow.

- Make sure unit is level.

- Setting the temperature to the lowest setting is not the optimal solution due to the condensation issues. The value we have preset on the cooling unit is a sound compromise between cooling the inside of the enclosure and the accumulation of condensation.

In harsh environments involving high temperatures, wash-down requirements, heavy particulate matter or the presence of chemicals capable of damaging components (NEMA 4 or 12 environments), ambient air must be kept out of the enclosure. Pfannenberg Cooling Units seals out the ambient air, cooling and re-circulating clean, cool air throughout the enclosure.

Pfannenberg offers Critical Thermal Management Solutions for Maximum uptime and efficiency.

Find the previous articles of this "Technology of Cooling" serie: Cooling with Filterfans® and Cooling with Closed Loop Air to Air Heat Exchangers.

Read the last part of this "Technology of Cooling" serie: Closed Loop Liquid Cooling Solutions