Pfannenberg, the specialist for industrial thermal management solutions and signaling technology will be exhibiting for the first time at Drinktec, the world's leading trade fair for the beverage and liquid food industry to be held in Munich from 11 to 15 September 2017.

Pfannenberg will be at stand 138 in Hall B3 showing tough, efficient thermal management solutions and signaling technology for the beverage and liquid food industry.

Visitors will be able to see the latest signaling technology and thermal management solutions for the food and beverage industry at stand 138 in Hall B3. Exhibits will include cooling units with corrosion resistant stainless-steel covers and robust signaling devices with high IP classifications. These products are designed for the toughest environments and are therefore suitable for use where liquids are processed and in production systems which require frequent cleaning.

A demo stainless-steel cabinet demonstrating these features will show a NEMA cooling unit, an air/water heat exchanger including a water jet test, a DTT top-mount cooling unit, a stainless steel rainhood and filterfans in stainless steel design.

"Food production places great demands on manufacturing technology. Our efficient, reliable and tough cooling and signaling technology guarantees maximum machine availability in the fast-cycling and highly dynamic processes in the food and beverage industry, starting with raw material processing through manufacture and quality control to packaging," explains Annarita Amadei, Industry Group Manager Food and Beverage at Pfannenberg.

IoT-enabled packaged solution

The communication-enabled cooling units in the εCool X series that will be exhibited are ideal for companies wanting to make their production fit for Industry 4.0 and at the same time improve machine availability. These thermal management solutions for electrical enclosures can be integrated directly in the user's automation systems. If required, they can also provide relevant device parameters via the Cloud for remote maintenance. Users benefit from customized maintenance, cost-efficient service and better machine availability thanks to preventative maintenance.

Reliable cooling

Modern production systems such as filling lines are usually permanently in operation. The cooling units and filterfans from Pfannenberg are fitted with IP 56 housing and corrosion-proof stainless-steel covers which makes them the optimum solution for the economical cooling of electrical enclosure technology.

Exhibits at Drinktec will include the new compact 6301C cooling units from the εCool 6000 series. Their power, and their compact design in particular, make them suitable for use in a wide range of applications.

Despite their space-saving design they offer the same energy efficiency, service friendliness and cut-out compatibility as the standard models: they cut energy consumption compared to traditional cooling devices by up to 43%, with a further 10% reduction in standby operation.

Tailor-made process cooling

In particularly sensitive areas of food and drink manufacture, the maintenance-free air to water heat exchangers and the EB series industrial chillers allow economic system solutions which work independently of the ambient air. Typical areas of application are filling lines and packaging systems. Pfannenberg chillers – with cooling capacities from 3.2 to 148.8 kW – cool sophisticated electronic systems. Both standard ready to-use units and fully customized ones can be provided.

This will be demonstrated at Drinktec with the EB 95 WT. Starting from the compactly designed, highly efficient and easy to service standard unit, this chiller can be equipped with several additional features to match specific applications.

For example, all devices can be equipped with a hydraulic bypass, a SMP55 controller with error messages panel and a ASI communication module enables the unit to be integrated the in the customer’s system. The EB devices are UL certified and can be used at ambient temperatures from -20 °C to +45 °C. All chillers in the range allow users to benefit from lower energy and operating costs, space-saving installation, high reliability and long machine life.

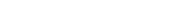

Robust signaling technology With high levels of ambient noise, the manufacture of beverages and liquid food makes serious demands on signaling technology. The status of packaging, laser inscription or filling machines and lines must be permanently displayed so that response times can be optimized and costly downtime minimized. Warning lights and acoustic alarms must signal hazards, risks or technical faults immediately, even in the vicinity of noisy conveyors operating at full capacity. Against this background, combinations of visual and audible signaling devices are the best choice.

With high levels of ambient noise, the manufacture of beverages and liquid food makes serious demands on signaling technology. The status of packaging, laser inscription or filling machines and lines must be permanently displayed so that response times can be optimized and costly downtime minimized. Warning lights and acoustic alarms must signal hazards, risks or technical faults immediately, even in the vicinity of noisy conveyors operating at full capacity. Against this background, combinations of visual and audible signaling devices are the best choice.

Signaling technology suitable for operation in production environments such as these will be exhibited:

- The BR 50 stacklights: This device is of a modular construction and uses sound and flashing, blinking or solid lights to signal statuses and dangerous situations reliably.

- The QUADRO and LED-HI multi function lights

- the PYRA sounder/flashing light combinations

- the PATROL and DS sounders

All of which are suitable for use in the demanding conditions of the drink and liquid food industry, will also be exhibited.