Customer Requirement

An OEM machine builder in the Marine industry needed a thermal management solution that was NEMA Type 4/4X rated, but also resistant to highly corrosive salt spray (fog). In an industry that encounters very harsh environments, it is crucial to be able to have a product that will be able to withstand such conditions.

Read More

Topics:

Air Water Heat Exchangers,

Thermal Management

Pfannenberg, the specialist for industrial thermal management solutions and signaling technology will be exhibiting for the first time at Drinktec, the world's leading trade fair for the beverage and liquid food industry to be held in Munich from 11 to 15 September 2017.

Pfannenberg will be at stand 138 in Hall B3 showing tough, efficient thermal management solutions and signaling technology for the beverage and liquid food industry.

Read More

Topics:

Thermal Management,

Industrial Safety & Signaling Solutions,

Trade Show

Customer Requirement

Pfannenberg worked with a bakery end user to develop a cooling solution for their control cabinets. Most of the OEM equipment installed in the bakery called for air conditioners to cool the drives. PLCs and additional electronics. Most times Cooling units can be a convenient and effective method for cooling electronics, except when located in dusty, humid areas within the plant.

These AC units failed regularly and had to be replaced. This was not a sustainable solution as the customer had constant issues with clogging coils and overheating panels.

Once a panel overheated they had to either: not operate the machine, or operate the cabinets with the doors open. This would let all the contaminants that were hurting the AC units into the cabinet, damaging the drives and other components.

Read More

Topics:

Air Water Heat Exchangers,

Thermal Management

An end user turned to Pfannenberg for assistance with managing their enclosure temperatures in a particularly harsh environment. The company produces high-quality construction and installation materials from wood fiber.

Read More

Topics:

Enclosure Cooling,

Cooling Units,

Thermal Management

Customer Requirement

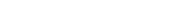

An OEM Milling component manufacturer which develops processing centers for the precision boring and milling high-precision components needed critical thermal management for their machine’s control electronics. The systems are designed using relatively tall electrical enclosures to minimize that installation space. This compact design fosters the development of heat pockets.

Read More

Topics:

Cooling Units,

Thermal Management

Condensation is one of the biggest dangers for electrical enclosures. As long as the components operate under load, their own warmth prevents water from condensing. If the process is switched off, the electronics cool down. This is where Pfannenberg control cabinet radiant heaters and fan heaters provide additional protection for your electronics.

How to Choose the Best Heater for your Electrical Enclosure?

Read More

Topics:

Thermal Management,

Heaters

Pfannenberg products ensure that manufacturing operations are up and running - especially during the holidays when many manufacturing lines are always online. Read below on just a few example applications on how Pfannenberg supports these product lines and keeps them running.

Part 1 – Candy Canes:

Candy Canes - The go-to holiday candy. As a child, they are passed out and enjoyed by many, and as adults they are necessary for almost any holiday decoration. This peppermint candy involves very delicate care when being processed. There are many differences in temperature to heat up or cool down – just enough that it maintains flavor and will not ruin the product quality. All throughout the manufacturing process of candy canes, temperatures are critical. At certain stages, the temperature needs to be increased to help form the canes, then at other parts it needs to be cooled so that it can be mixed to perfect flavor and coloring.

Read More

Topics:

Air Water Heat Exchangers,

Thermal Management,

North America,

Packaged Chillers,

Food & Beverage,

Chillers

Tis’ the season – for we have many things to be thankful for this year! With the holiday season quickly approaching, we are taking the time to reflect on all of our blessings. Common dishes for most Traditional American Thanksgivings include turkey, cranberry sauce, stuffing, green bean casseroles, fresh baked rolls, and pumpkin pie. Most of us look forward to this holiday all year, for it is a time to be thankful and gather with loved ones.

Turkey processors themselves have to really work all year to meet this spike in demand around the holidays. Innovation in new packaging technology allows these processors to be able to serve a fresh Turkey that has a longer shelf life without chemicals. Pfannenberg’s thermal management and chiller products are a perfect fit for aiding in the packaging side of Turkey processing.

Read More

Topics:

Thermal Management,

North America,

Food & Beverage,

Chillers

In today’s modern lifestyle, frozen foods have played a major role in providing convenience to customers. Pies – a family fall favorite, often take time that many families do not have. This is the time of the year where kids are back to school, parents are running all over doing drop-offs and pick-ups, rushing to work; taking the time to bake or make a full meal is often difficult. Large industrial bakeries can manufacture roughly 200,000 frozen pies a day. There is a high demand in this modern age for this aspect of convenience.

Read More

Topics:

Air Water Heat Exchangers,

Thermal Management,

North America,

Food & Beverage,

Bakery

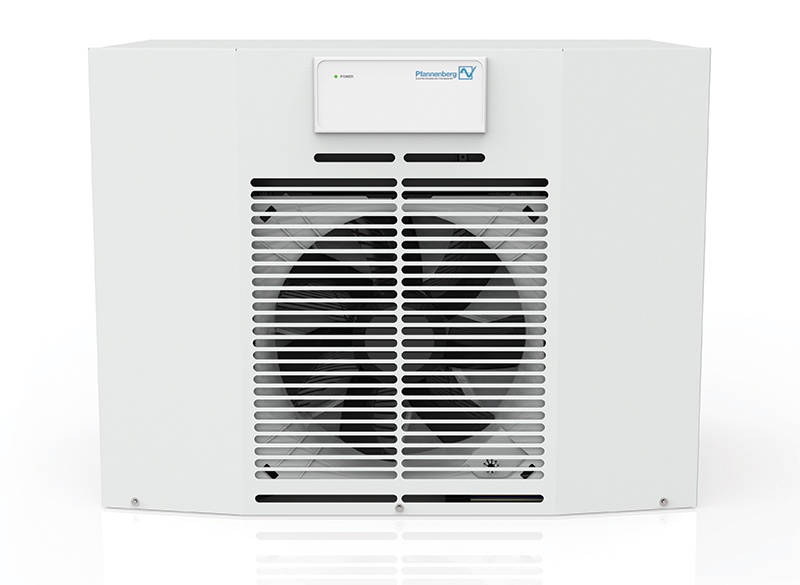

Preventing enclosure overheating in the summer can be a challenge for many factories, where temperatures can rise fast during hot days!

Read More

Topics:

Enclosure Cooling,

Thermal Management